capability

FPC capability

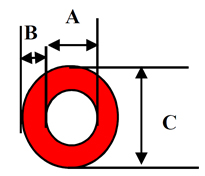

| NC Drilling | ||||||||

| Layer Count | Minimum size(A) | Normal sizePAD(C) | Single side hole ring(B) | Minimum size PAD |  |

|||

| Double side | 0.10mm | 0.35mm | 0.125mm | 0.30mm | ||||

| 1L+1L | 0.15mm | 0.40mm | 0.125mm | 0.35mm | ||||

| 3L or more | 0.15mm | 0.45mm | 0.15mm | 0.4mm | ||||

| 4L or more | 0.2mm | 0.5mm | 0.15mm | 0.45mm | ||||

| Flex-rigid | 0.2mm | 0.5mm | 0.15mm | 0.45mm | ||||

| Drilling size range | 0.1mm~6.5mm | |||||||

| Hole tolerance | ±0.01mm | |||||||

| True position size | ±0.05mm | |||||||

| Copper Plating | ||||||||

| Type | Copper weight range | Normal Capability | Special Capability | Remark | ||||

| Sculptural | Copper Plating | 300±100u” | 400±120u” | |||||

| Double side | 450±150u” | |||||||

| 1L+1L | 10~30u” | 600±200u” | 800±250u” | |||||

| 3L or more | ||||||||

| 4L or more | ||||||||

| Flex-rigid | 600u” or more | |||||||

| Remark | Drilling Minimum siz 0.1mm,Aspect ratio8:1 | |||||||

| Etching | ||||||||

| Trace width / space | Layer Count | Copper Weight | Minimum trace width | Minimum trace space | Remark | |||

| Singel side | 1OZ | 3mil | 3mil | |||||

| 1/2OZ | 2mil | 2mil | ||||||

| 1/3OZ | 1.8mil | 1.8mil | ||||||

| Double side | 1OZ | 3mil | 3mil | Normal Copper Plating 300±100u” | ||||

| 1/2OZ | 2.5mil | 2.5mil | ||||||

| 1/3OZ | 2mil | 2mil | ||||||

| 1/3OZ | 1.8mil | 1.8mil | Only PTH Cu | |||||

| Coverlay/Stiffener | ||||||||

| Stiffener | Material type | Tolerance | Special tolerance | Remark | ||||

| CVL | ±0.3mm | ±0.2mm | CVL Spilled glue≦0.10mm Minimum SUS size3mm X 5mm |

|||||

| PI,FR4 | ||||||||

| SUS | ||||||||

| Adhesive | ||||||||

| Coverlay | Material type | Minimum Opening | Minimum space from Opening to inner pattern | |||||

| CVL | 0.5mm | 0.30mm | ||||||

| Printing | ||||||||

| Printing | Project | Project | Normal | Minimum | Remark | |||

| Silkscreen | Tolerance | ±0.3mm | ±0.2mm | The color is specified by the customer | ||||

| Minimum | 0.12mm | 0.1mm | ||||||

| Height | 1.0mm | 0.8mm | ||||||

| Solder Mask Hot bake | Tolerance | ±0.35mm | ±0.3mm | |||||

| Thickness | 20±10um | |||||||

| Solder Mask development | Deviation | ±0.075mm | ±0.05mm | |||||

| Mask spacing | 0.1mm(min) | |||||||

| Minimum Opening | 0.4mm X 0.4mm | |||||||

| Thickness | 20±10um | |||||||

| Punching | ||||||||

| Project | Project | Normal Tolerance | Minimum Tolerance | Remark | ||||

| Etching | Pitch to Pitch | ±0.3mm | ±0.2mm | The smallest tolerances require precision molding | ||||

| Total Pitch(≦50mm) | ±0.3mm | ±0.2mm | ||||||

| Punching | First Gold Finger Pin to Dimensions | ±0.01mm | ±0.05mm | |||||

| Gold Finger to Dimensions | ±0.075mm | ±0.05mm | ||||||

| Dimensions | 0.1mm | |||||||

| Minimum Angle R | 0.2mm | 0.15mm | ||||||

| NPTH to NPTH | ±0.075mm | ±0.05mm | ||||||

| NPTH to Dimensions | 1.5mm | 1.0mm | ||||||

| Trace to Dimensions | 0.2mm | |||||||

| Minimum Punching hole | 0.5mm | |||||||

| NPTH Tolerance | ±0.5mm | |||||||

| Surface Treament | ||||||||

| Project | Project | Ni/Au | spec | Characteristic | ||||

| Hard gold plating | Normal | Ni | 2um~6um | |||||

| Au | 0.025~0.075um or 0.05um(min) | |||||||

| Thick Gold | Au | 0.2um~0.8um | ||||||

| Immersion gold | Normal | Ni | 0.75um~2um | |||||

| Au | 0.025~0.075um | |||||||

| OSP | thickness | OSP | 0.2um~0.5um | |||||

| Thickness | ||||||||

| Board thickness tolerance | 1L、2L | ±0.03mm(±10%) | ||||||

| 3L or more | ±0.05mm(±10%) | |||||||